Remote Monitoring

Monitor and control your energy system 24/7. Our custom control systems allow multiple staff from your team to access the same critical data that we do – ensuring your facility receives the best possible service.

Overview

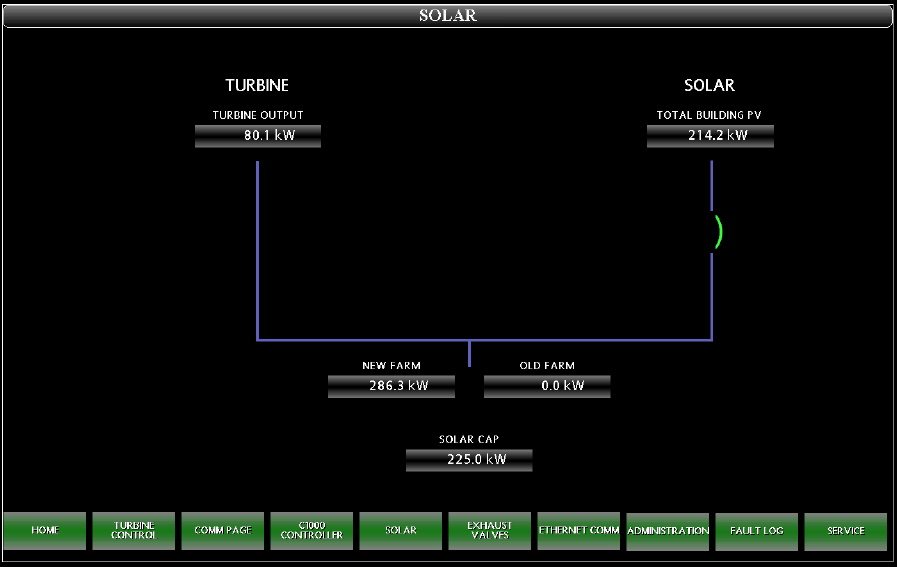

At Vergent, we monitor your Capstone Microturbine system data so that we can quickly respond to any concerns before they become more serious.

Rather than allowing small issues to go unnoticed and worsen over time, remote monitoring systems allow us to react to power generation problems immediately, either via computer controls or by dispatching a technician.

Our remote monitoring controllers were conceptualized, developed and qualified by teams trained by Capstone Green Energy. This custom equipment was developed to improve on-site controls and integrate more effectively with end-use customer facilities.

Advanced Microgrid Controls

How It Works

Our remote operation team will monitor and oversee your microturbine system, ensuring the safe and reliable supply of energy at your site. We work in collaboration with your team, preparing a remote monitoring plan to provide you with immediate alerts and prompt response for unexpected behavior of any connected equipment. Our team will also provide regular diagnostic updates and notification of planned and/or unplanned maintenance needs.

Why Us

Since Vergent’s founding ten years ago, our team has helped hundreds of customers install some of the cleanest and greenest energy generation systems in North America. The proof is in the projects, so judge us by our successful track record.