Decarbonize Your Building

At Vergent, we provide solutions for buildings. Our energy solutions cut operating costs, increase reliability and reduce emissions.

Overview

During conventional, separate power and heat generation, nearly two-thirds of energy is wasted, discharged to the atmosphere as heat during generation, transmission, and distribution.

With modern Combined Heat and Power (CHP) systems, the capture and reuse of heat that would otherwise be wasted helps generation systems to achieve efficiencies of over 90 percent, compared to 45 percent for typical technologies (e.g., conventional electricity generation and an on-site boiler).

Because of this increased efficiency, CHP systems emit less carbon emissions than separate heat and grid power.

CHP can help you meet your decarbonization goals

Frequency Asked Questions

Buildings that purchase their electricity from a central utility grid and generate thermal energy from a separate process (such as a boiler or chiller), are producing energy less efficiently when compared to the CHP system that performs the same role onsite with only one energy system.

CHP is a source of reliable baseload power and thermal energy generation. In most of North America, a well-designed and operated CHP system produces less Greenhouse Gases (GHGs) than the grid power and separate thermal energy that it offsets.

The GHG emissions of non-baseload grid sources vary from state to state, but in almost all U.S. states, a CHP system represents a significant reduction in GHG emissions versus grid generation sources.

For example, in Minnesota, the non-baseload electricity generation sources emit 1,544 lbs/MWh of GHG equivalents, according to 2019 U.S. Environmental Protection Agency (EPA) data. In Massachusetts, which has a much cleaner power grid, the GHG emissions created by non-baseload electricity generation sources is 899 lbs/MWh.

Electricity from the grid, combined with a boiler that emits CO2 at 525 lbs/MWh, has a total CO2 emissions rate of 650 lbs/MWh.

By contrast, a hot water CHP system that's 76 percent efficient and fueled by natural gas emits approximately 571 lbs/MWh of CO2, which represents a reduction in GHG emissions of 12 percent.

After factoring in Nitrogen Oxides (NOx) reduction, the GHG equivalency reduction is even greater. This calculation demonstrates how even in states (or provinces) that have fairly clean power grids, like Massachusetts, a CHP plant will help a facility to lower their GHG emissions.

Looking at another extreme example, the Canadian province of Ontario has one the lowest emitting electricity systems in the world. In 2020, Ontario’s grid was 94 percent GHG emission free. Yet even with such a clean grid, Ontario heavily relies on natural gas generation for 28 percent of total generating capacity to avoid blackouts and fill the void left from intermittent renewable sources. Reducing the reliance on natural gas generation further would have catastrophic consequences on grid stability in addition to the cost of power for Ontario ratepayers.

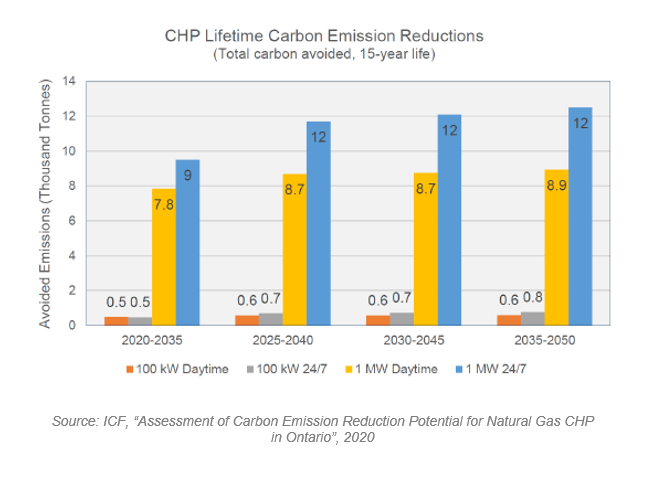

ICF, a global consulting and technology services company, in a report assessing the "Carbon Emission Reduction Potential for Natural Gas CHP in Ontario" showed that a natural gas CHP system installed in Ontario reduces GHG emissions when compared to electricity supplied by the grid; in fact, a 1 Megawatt (MW) CHP system installed in 2020 operating 24/7 reduces over 9,000 tons of carbon over a 15-year period.

This calculation demonstrates that an efficient use of fossil fuels in all jurisdictions reduces carbon output when compared to local utility grids.

For ultra-clean CHP, we recommend building your system around a microturbine. Microturbines have the lowest pollution emissions profile of any commercially available combustion technology. The NOx and Carbon Monoxide (CO) emissions of microturbines are ultra-clean because of the low air-fuel premix and tightly controlled combustion process that is part of this technology. Microturbine emissions are so low that they do not require any exhaust after-treatment in almost all North American jurisdictions. If further pollutant reduction is required, microturbines can be outfitted with a passive catalyst that, unlike an Silicon-Controlled Rectifier (SCR), does not use urea.

You also have the option fuel your CHP plant with biogas (or RNG). Microturbines can operate with biogas just as well as they would with natural gas. There are hundreds of biogas CHP plants in North America operating microturbine CHP plants successfully for decades. We recommend The biogas will need to be conditioned prior to injection into the CHP system. If a local source of biogas is not available, customers can procure RNG from a variety of sources. RNG is biogas that has been conditioned to be similar to natural gas, and is injected into the interstate natural gas pipeline system.

Offset your fuel consumption with carbon credits or renewable energy credits. Natural gas CHP can become carbon neutral when paired with carbon credits and/or Renewable Energy Certificates (RECs). This is a fairly simple contractual process that allows the CHP system to offset its local emissions with offsite reductions. As more renewable energy is added to the grid, customers can increase their usage of low carbon fuels and attributes to produce a greener energy stream.

Altneratively, you can choose a hybrid microgrid. CHP is an excellent backbone for a renewable microgrid that can integrate solar generation, small scale wind generation and battery energy storage. A baseload CHP system can provide the resiliency and thermal energy needed for a facility, supplemented by renewable energy generation for an overall lower carbon footprint capable of operating as net zero.

CHP systems are capable of operating with hydrogen. Many CHP systems, including microturbines, can run on some percentage of hydrogen fuel blended with methane. As more sources of green hydrogen (i.e. hydrogen not produced by fossil fuels) become commercially available, hydrogen CHP will become a more accessible option.

Electrifying building heat in most places is nearly impossible: Buildings in northern climates require a great deal of heat, much more than the grid infrastructure can currently provide.

Mass electrification will be incredibly expensive: The transition will require immense spending on converting boilers and chillers to heat pumps and increasing electrical services in every building. Building owners, factories and utility ratepayers will be forced to shoulder the economic cost of electrification. Electrifying space heating in Massachusetts with current Renewable Portfolio Standard (RPS) content around $.17/ kWh, which is the equivalent of $50/MMBtu gas. Renewable Natural Gas is available for less than that price so the blended cost would be much less.

Electrification will force grid power prices to rise exponentially: The amount of new power generation needed will greatly exceed the current capacity of renewable energy and energy storage. More power plants will need to be built and will need to operate on fossil fuels. This cost will drive power prices up significantly in a short period of time and the grid will become more GHG-intensive as a result.

No matter what happens, CHP will remain a smart energy hedge. The high cost of grid power makes CHP a financially attractive prospect for building owners, compared to the lower energy costs of electricity generation onsite.

Reasonable approaches are needed. CHP can and should be part of the effort to green building heating. The CHP industry and CHP users will need a spot at the table to ensure that common-sense approaches are given full consideration by policymakers.

Many building owners choose to install a CHP system instead of a traditional backup generator because a CHP can provide the same energy security. Compared to a traditional backup generator, CHP has the ability to provide an economic payback due to its 24/7/365 operating profile.

According to the U.S. Department of Energy, “Combined heat and power (CHP) has proven effective in ensuring uninterrupted electric service through multiple major disasters in hospitals, schools, and places of refuge. CHP systems simultaneously generate electricity and produce thermal energy, maintaining needed power, hot water and space conditioning services on—site at high efficiency. And, unlike diesel back-up generators, CHP typically does not require over-land fuel deliveries.”

Vergent is a clean energy developer

Since we were founded more than ten years ago, our team has helped develop some of the cleanest and greenest energy generation systems in North America. The proof is in the projects, so judge us by our successful track record.

Is Grid Power In My State Clean?

Plan For The Future

Maximize Your Assets