Capstone Microturbines

The microturbine is in a class of its own. Vergent is proud to offer this unparalleled clean energy technology to North America, which we’ve done since 2014.

Overview

Vergent provides customized microgrid solutions and on-site energy technology systems to help customers meet their carbon reduction, energy savings and resiliency goals. Microturbines run on natural gas, landfill gas, digester gas, renewable natural gas (RNG), associated gas, liquid fuels, and even hydrogen. Well-suited for multiple types of heat recovery, microturbines excel at utilizing waste head to efficiently produce hot water, steam, chilled water, or process heating.

In addition to generating power and heat year-round, the Capstone microturbines can operate as life-safety backup generators to power critical loads during emergencies. Many customers use CHP to extend – or avoid – costly replacements to their existing HVAC equipment. Our specialists will customize and engineer the heat recovery solution for each project based on its unique needs.

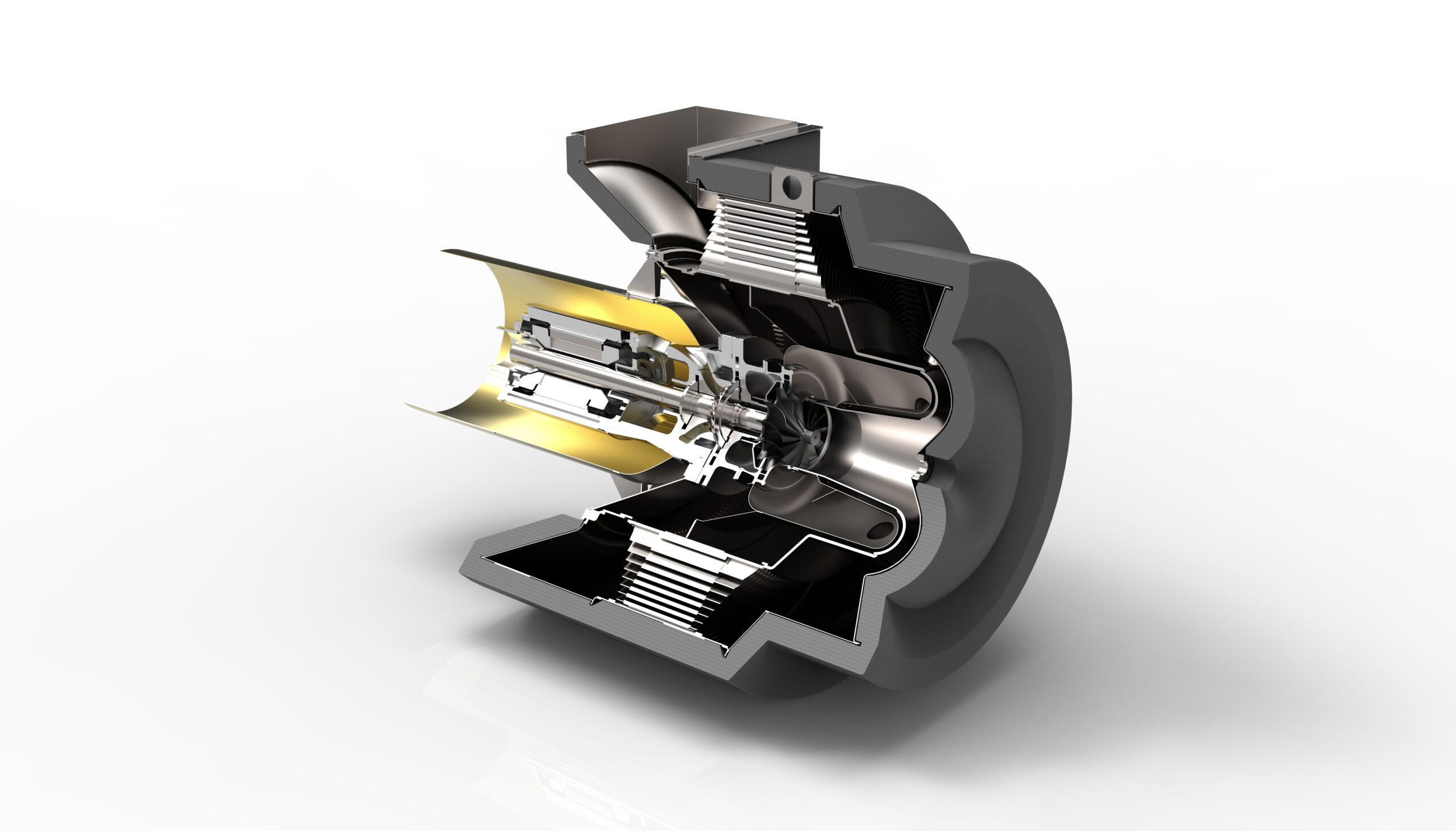

With over 100 technology patents, these systems combine an aero-derivative turbine, a magnetic generator, and advanced inverter-based power electronics. The true beauty of this technology lies in Capstone’s patented air bearings, which allow for zero friction and require no lubrication oil or cooling system.

Oh, and did we mention? The microturbine has only one moving part!

Next Generation Technology

- Air-bearing design

- No lubricating oil or coolants required

- Ultra-low Emissions

- Less than 5ppm NOx

- Quiet operation

- 65 dB at 10 meters

- Multi-fuel capability

- Adaptable to gaseous and hydrogen

- UL certified

- UL 1741/SA and UL2200

- Remote monitoring

- Complete view of performance at all times

- Modular design

- Easy and simple to scale

- Inverter-based output

- Clean, UPS quality power

-

Patented Air-Bearing Technology

-

One Moving Part

-

Ultra-Low Emissions

-

High Efficiency Systems

-

Scalable, Modular Design

-

Lowest Maintenance Cost of any Generation Technology

-

Fuel Flexibility

-

Compact Size

-

Microgrid Ready

-

Operate with or without a Utility Grid

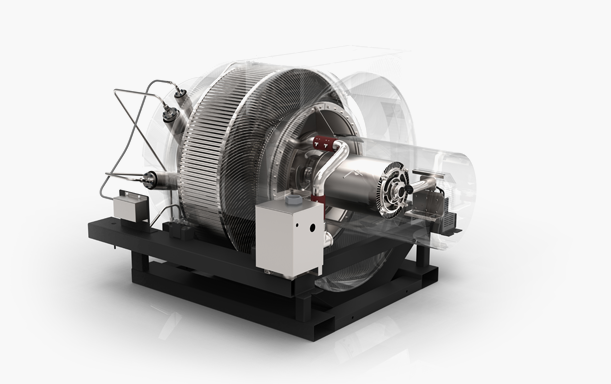

The air bearing allows the microturbine to operate with zero friction and zero “wear and tear”. The critical Capstone technological innovation is the use of air bearings. Capstone is the only company that uses air bearings in the hot section of a gas turbine. Air bearings enable the microturbine to operate without the use of oil or other lubricants. There is no oil in the microturbine, which means no oil changes. The system is also air cooled, so there are no coolants or separate cooling systems used in the microturbine.

The air bearing allows the microturbine to operate with zero friction and zero “wear and tear”. The critical Capstone technological innovation is the use of air bearings. Capstone is the only company that uses air bearings in the hot section of a gas turbine. Air bearings enable the microturbine to operate without the use of oil or other lubricants. There is no oil in the microturbine, which means no oil changes. The system is also air cooled, so there are no coolants or separate cooling systems used in the microturbine.

Unlike reciprocating engines which have hundreds of moving parts, the microturbine has only one single moving part. The turbo-generator shaft rotates at extremely high speeds to produce power as cleanly and efficiently as possible. The single moving part means that there is less likelihood of system failure or need to maintain and repair. The shaft contains the generator, compressor and turbine on a single assembly, rotating at up to 96,000 RPM.

Unlike reciprocating engines which have hundreds of moving parts, the microturbine has only one single moving part. The turbo-generator shaft rotates at extremely high speeds to produce power as cleanly and efficiently as possible. The single moving part means that there is less likelihood of system failure or need to maintain and repair. The shaft contains the generator, compressor and turbine on a single assembly, rotating at up to 96,000 RPM.

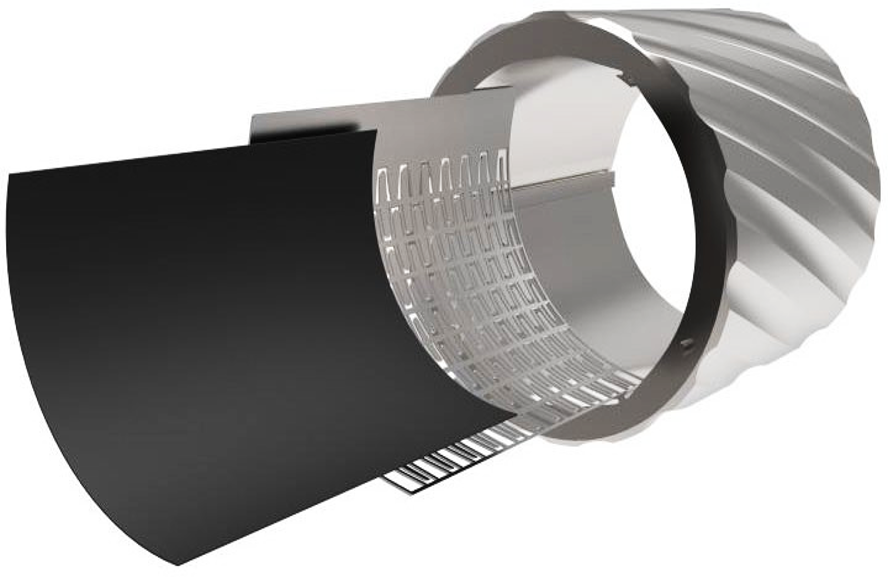

Vergent utilizes microturbines that provide customers with one of the cleanest generation technologies available today. Considerably cleaner than the cleanest reciprocating engines, microturbines are certified by the California Air Resources Board which demands the strictest emissions limits in North America.

Vergent utilizes microturbines that provide customers with one of the cleanest generation technologies available today. Considerably cleaner than the cleanest reciprocating engines, microturbines are certified by the California Air Resources Board which demands the strictest emissions limits in North America.

Combined Heat and Power (CHP) systems contribute to a cleaner grid because they can produce energy so efficiently. Generating and consuming energy at the same location means that microturbines eliminate power line losses and CHP utilizes the waste heat instead of emitting it into the atmosphere.

Injector staging allows for high part load efficiency. Continuous combustion creates combustion stability and low emissions. Modularity allows for maximum efficiency and resiliency.

Injector staging allows for high part load efficiency. Continuous combustion creates combustion stability and low emissions. Modularity allows for maximum efficiency and resiliency.

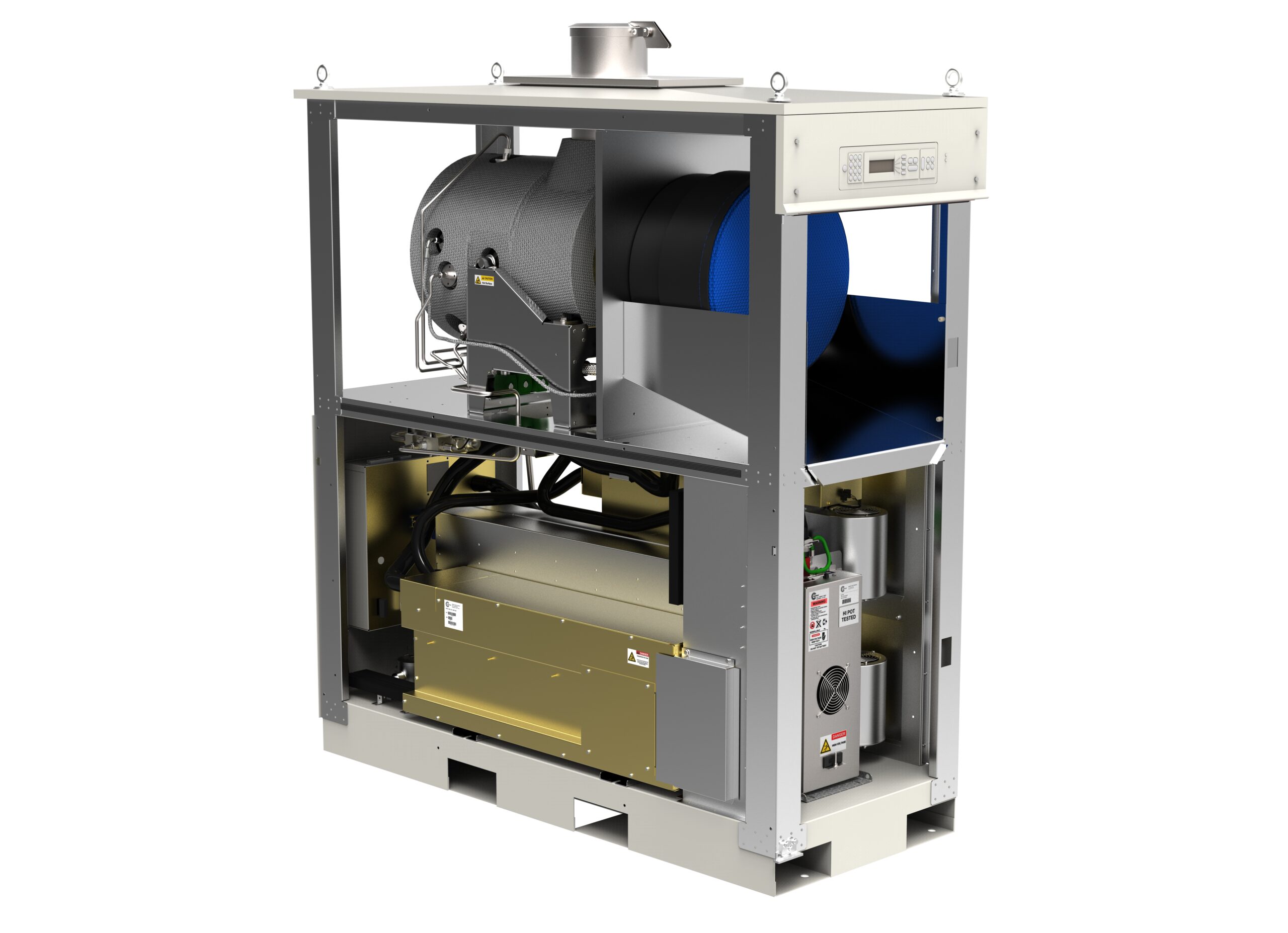

The use of smaller power blocks allows Capstone to deliver the most efficient generated power at partial loads. The one-megawatt package, for example, contains five 200kW power bays allowing it to operate at lower intervals at maximum efficiency by staging the individual bays as load increases. Each bay can operate independently, and maintenance can be performed on one bay at a time while the others continue to generate power.

The use of smaller power blocks allows Capstone to deliver the most efficient generated power at partial loads. The one-megawatt package, for example, contains five 200kW power bays allowing it to operate at lower intervals at maximum efficiency by staging the individual bays as load increases. Each bay can operate independently, and maintenance can be performed on one bay at a time while the others continue to generate power.

Backed by the Capstone Factory Protection Plan (FPP), there is no part or service that is excluded from coverage during the term of the agreement. The FPP is a fixed price for the term, with no inflation or overages.

Backed by the Capstone Factory Protection Plan (FPP), there is no part or service that is excluded from coverage during the term of the agreement. The FPP is a fixed price for the term, with no inflation or overages.

Microturbines can operate on a variety of fuels, such as natural gas, biogas, diesel, or propane, allowing for adaptability to local fuel availability and reducing dependence on a single fuel source.

Microturbines can operate on a variety of fuels, such as natural gas, biogas, diesel, or propane, allowing for adaptability to local fuel availability and reducing dependence on a single fuel source.

Capstone continues to expand and develop new fuel standards including for Hydrogen. Currently Capstone microturbines can safely run on a 30% hydrogen - 70% natural gas blend. Within the next few years, Capstone is expected to release retrofit kits that will allow microturbines to be fueled solely by hydrogen.

Due to their small footprint and lighter weight, microturbines can be easily integrated into existing buildings or facilities, minimizing the need for extensive construction or modifications.

Due to their small footprint and lighter weight, microturbines can be easily integrated into existing buildings or facilities, minimizing the need for extensive construction or modifications.

This includes fitting in elevators, basement, parking garages and other tight spaces simply too small for other equipment types.

A microgrid is a distribution network that incorporates a variety of Distributed Energy Resources (DERs) that can be optimized and aggregated into a single system. The integrated system can balance loads and generation with or without energy storage and is capable of islanding whether connected or not connected to a traditional utility power grid.

A microgrid is a distribution network that incorporates a variety of Distributed Energy Resources (DERs) that can be optimized and aggregated into a single system. The integrated system can balance loads and generation with or without energy storage and is capable of islanding whether connected or not connected to a traditional utility power grid.

DERs typically include dual-mode microturbines, reciprocating engines, solar photovoltaic (PV), wind turbines, fuel cells and battery storage.

Microturbines can function in both grid-connected and off-grid modes, providing energy security and resilience, particularly during grid outages or in remote locations.

Microturbines can function in both grid-connected and off-grid modes, providing energy security and resilience, particularly during grid outages or in remote locations.

Microturbines can be connected to electricity grids, and in the event of a widespread outage, can disconnect from the main grid to operate independently and supply electricity to homes and businesses that are connected to the microturbines electricity network.

Work with a team specializing in microturbine applications

Design

Installation

Ongoing Service + Support

Latest Projects

Our energy experts deploy innovative technical solutions customized to our customers’ unique energy, business, and climate needs.

- We listen and understand

- We work with you, not just for you

- We design and build

- You save money and gain energy freedom

- We stay with you for the life of the project

- We treat you as our partner and always deal honestly and openly

- We keep you informed at each step, so that you’re always in control