Thermal Recovery

Using Capstone Microturbines for thermal recovery not only improves energy efficiency but also reduces the overall energy consumption and carbon footprint of an operation.

Heat Recovery

Thermal energy can be just as valuable as electricity in our applications. When we perform an economic analysis, we examine the gas and electrical consumption at your facility to uncover the utility and energy savings.

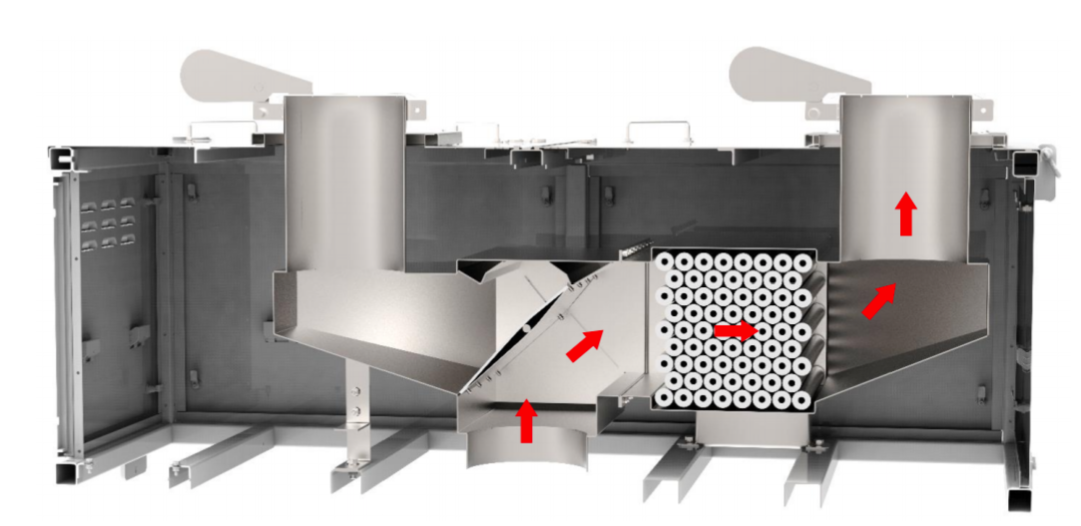

The unique design of microturbine technology allows customers to recover thermal energy that would otherwise be wasted in power generation from a single heat source – the exhaust of the turbine.

Waste heat is useful in a variety of applications: Industrial processes can inject exhaust heat for drying processes, healthcare facilities can recover exhaust heat to produce steam, and residential buildings can transform heat into free cooling in the summertime.

Our team will work with you to unlock maximum value from onsite generation for your operations. We’ve found that in some cases, thermal energy generated by microturbines can avoid replacement or extend the life of existing Heating, Ventilation, and Air Conditioning (HVAC) equipment.

Combined Heating and Power

Combined Cooling, Heating and Power

Heat Recovery Steam Generation

Direct Exhaust

Latest Projects

Our energy experts deploy innovative technical solutions customized to our customers’ unique energy, business, and climate needs.

- We listen and understand

- We work with you, not just for you

- We design and build

- You save money and gain energy freedom

- We stay with you for the life of the project

- We treat you as our partner and always deal honestly and openly

- We keep you informed at each step, so that you’re always in control